AMS

Artichoke Modular Sorter

The new generation of the Artichoke Modular System is based on the Swivel technology. It has been designed to be aggregate as multiple modules to reach high performances and high reliability.

The main technical features:

- Modular approach. The swivel can be composed according with the items to be sorted and the capacity required

- High density of wheels and high grip rubber coated wheels

- Brushless motors. Each module is autonomous and controlled by a brushless motors to guarantee high performances, flexibility and reliability

- Fully control of the rotation of the wheels. Possibility to control the angle position of the wheels during the transport and the sorting functions

- Fully control of the speed. Thank the brushless motor, each module can be setting up with a different speed to have a fully control of the sorting trajectories

- Minimising wear components. Only one belt is installed on each module

- Robust design. Handled parcels weighting up to 50kg

- Very high speed rotation. To cover 180° rotation are needed only 300ms

- High capacity of the system. Up to 6K parcels per hour

Main benefits:

- Modular elements based on the parcel dimensions and capacity required

- Minimization of friction mechanical components thanks to use the brushless motor technology

- Fast maintenance maximized by the modular design, allowing “Plug and Play” maintenance in case of failure

- Very low gap between the wheels surface and the mechanical frame to increase the stability of heterogeneous items (standard and small, flat, carton box, polybags)

- Bidirectional functionality. Designed to run in both direction according with the inbound and outbound process;

- Flexibility in its applications. Same system enables merging and sorting as well as alignment and the distribution with different trajectories.

Singulation System

Based on the AMS technology, SAIET Engineering is developing a new system able to singulate parcels coming from a bulk, to be processed in a standard sorter.

No similar systems are available on the market

This system is halved in size and has the lowest consumption compared to its competitor.

Our aim is the space reduction, that means reduction in facility costs and flexible layout design, to be adapted for new and existing systems.

Vision tool

Roller Conveyor 48Vdc

Fully designed and assembled by SAIET Engineering, the new concept of roller conveyors is born to respond to important issues:

- Go green tech

- High safety solution

- Low cost and very profitable (to face new markets)

- Short lead time

- Better spare parts management

- Better parcel buffering in the systems

Plug and play

Each module is completely independent and connectable to the pervious and following one

48Vdc Brushless motorized rollers

Exclusively produced for SE by SITEM, a reliable partner of our main supply chain

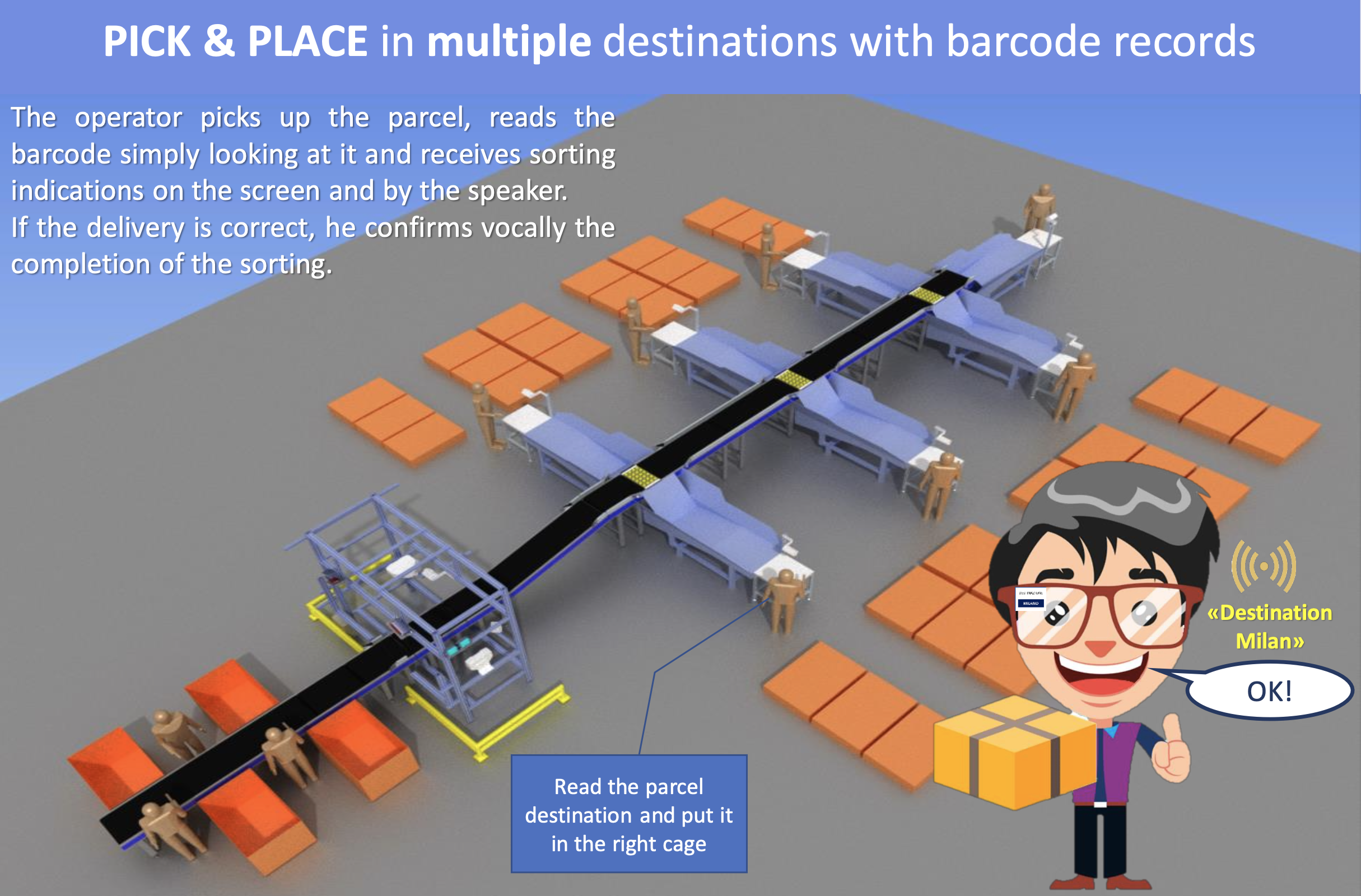

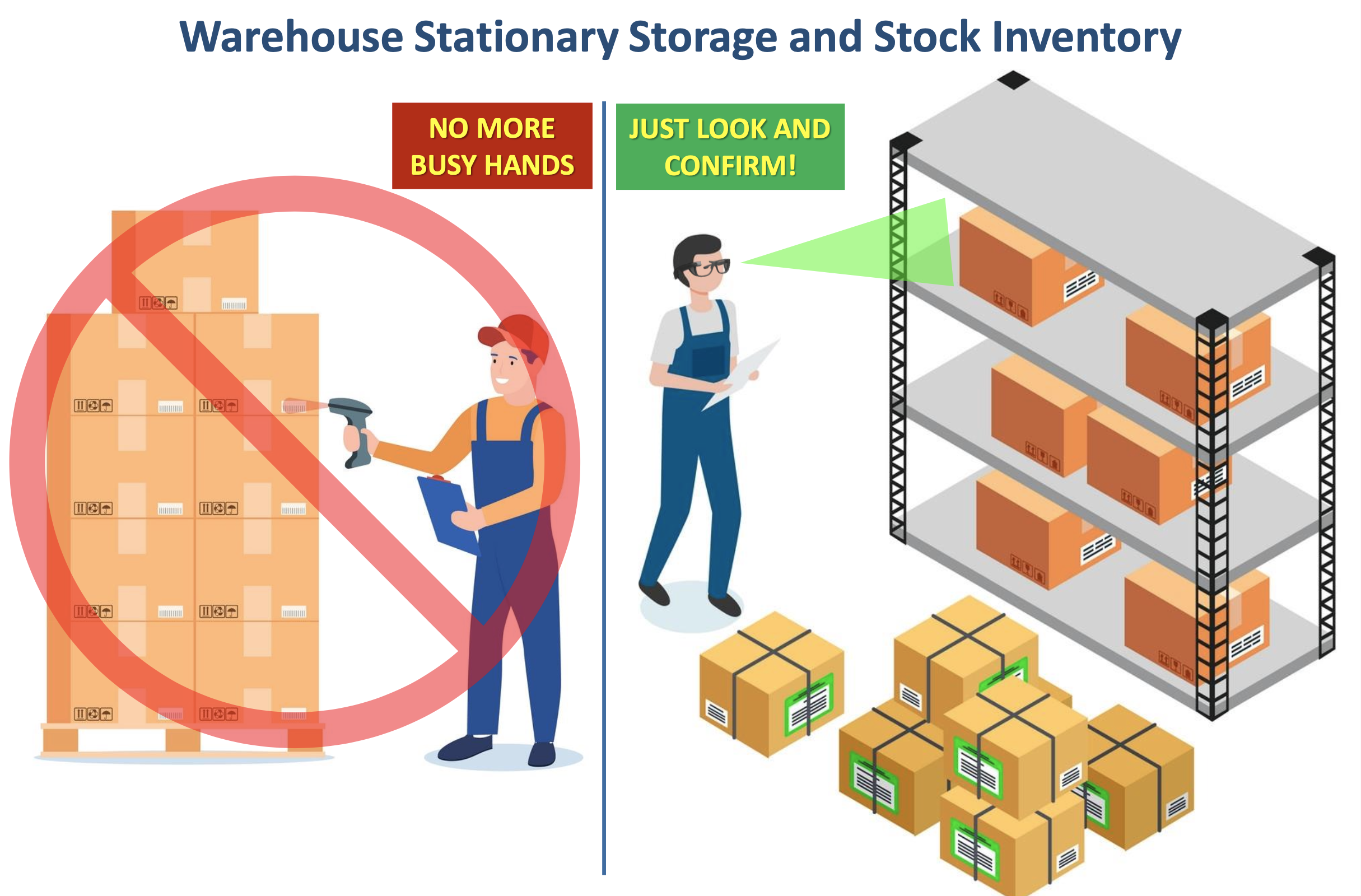

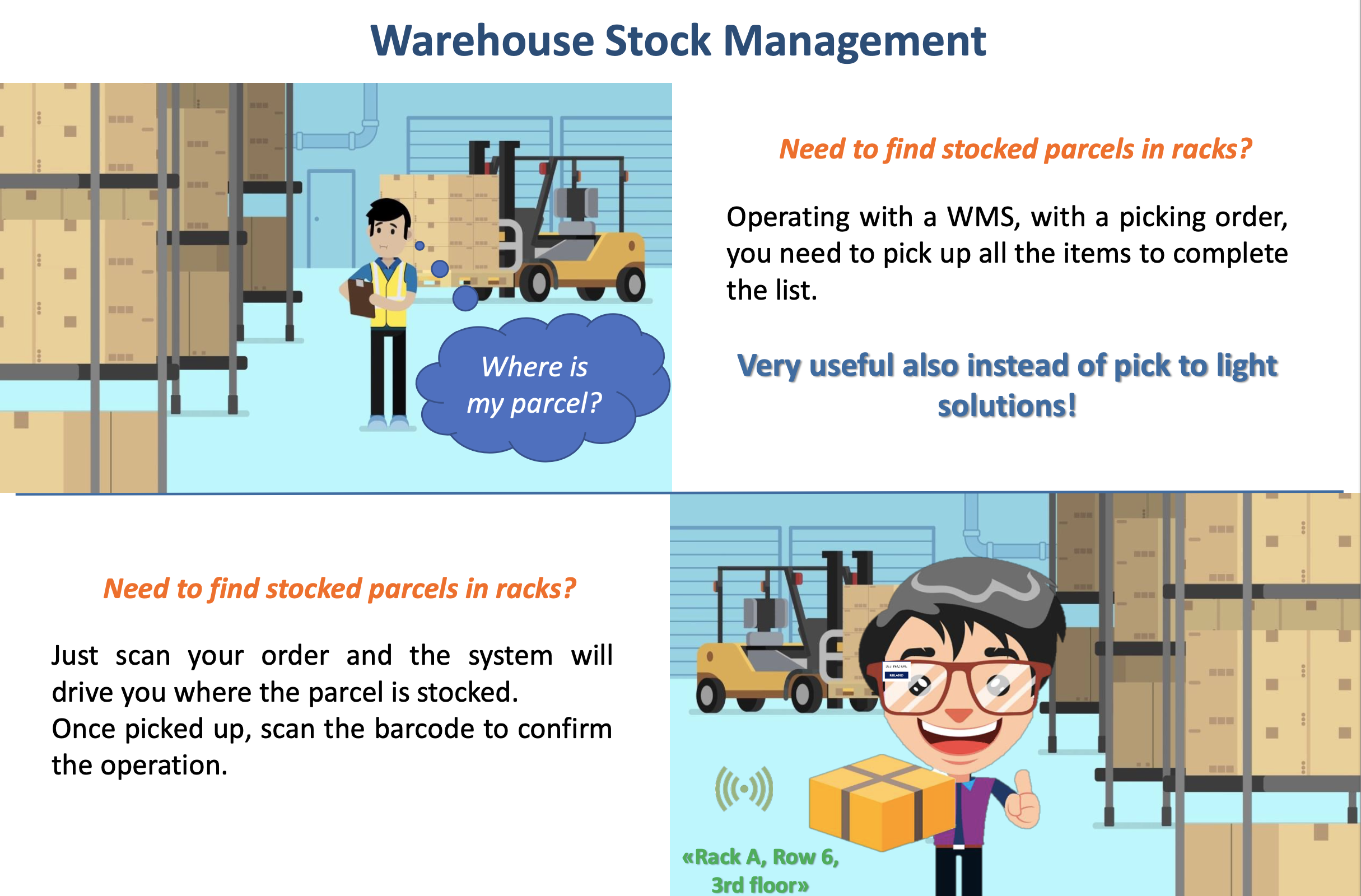

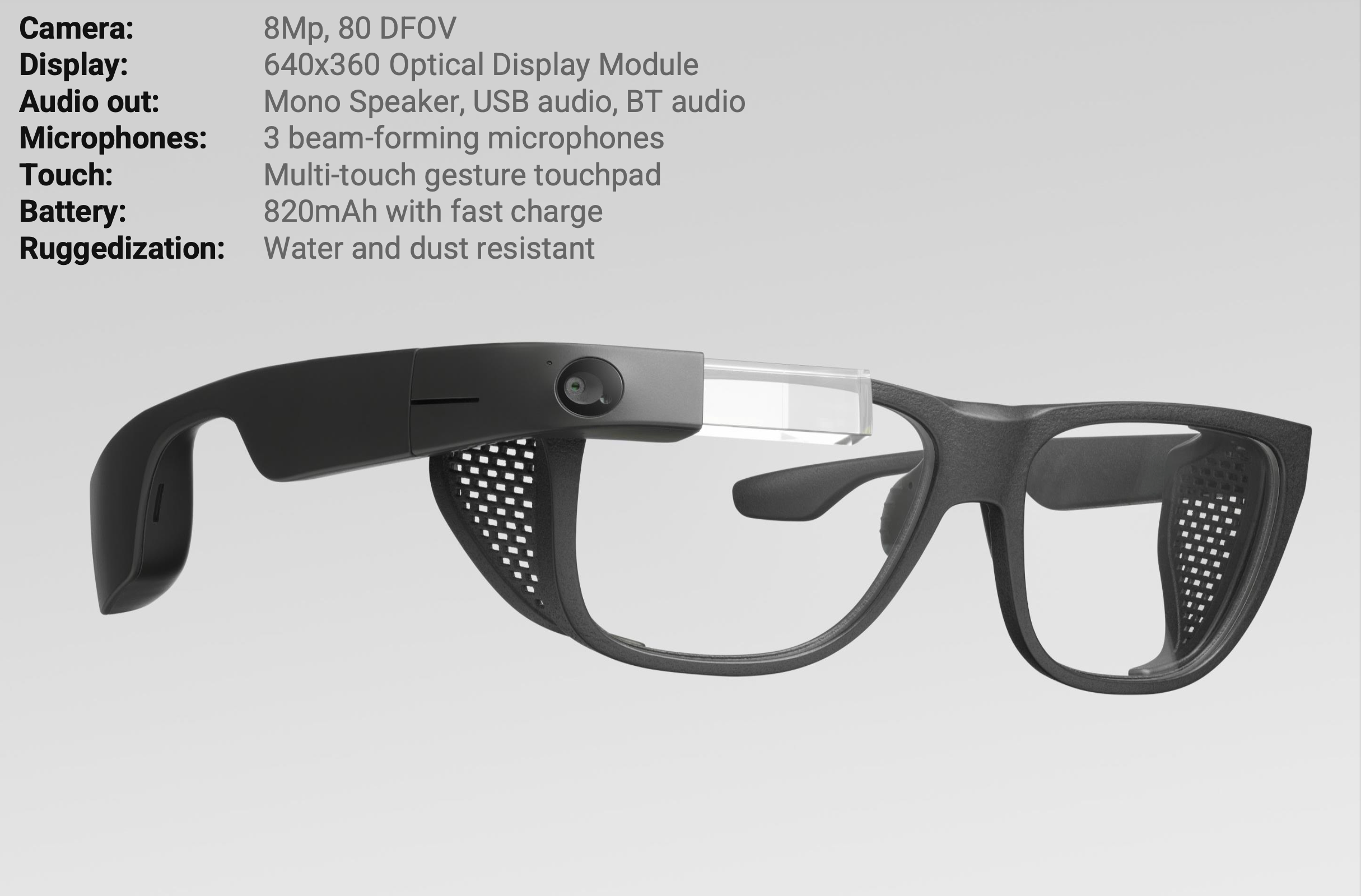

Smart glasses / Augmented Reality

Our solution for Augmented Reality with the use of Smart Glasses, ideal for the logistic operations, instead of the touch panels.

Available for pick & place, pick to light, order formations, stationery warehouse management, finger manual sorting.

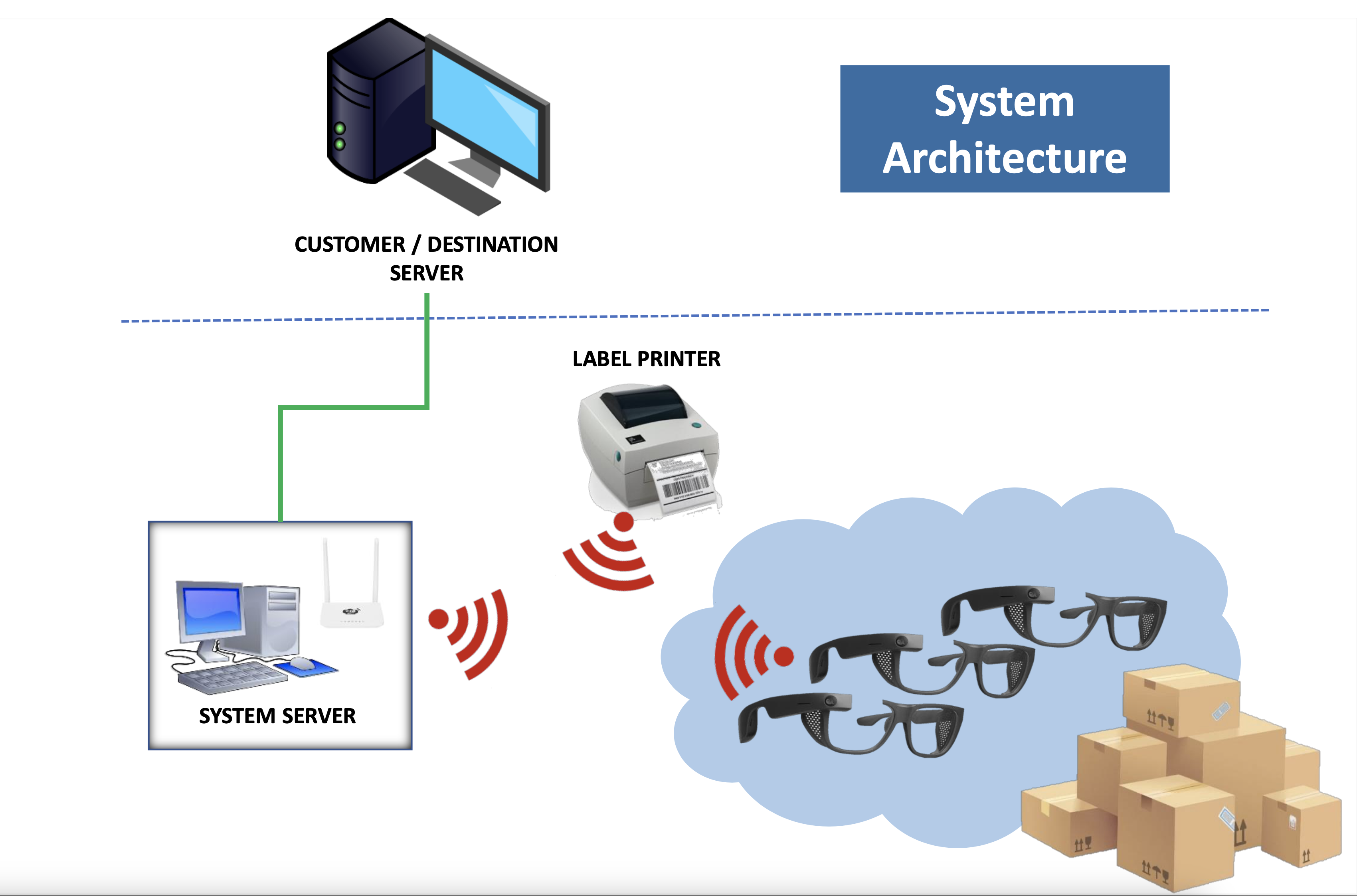

System Architecture for Augmented Reality.

AR Glasses logistic

Features of Smart Glasses Glass to light on finger conveyor Pick & Place Warehouse storage and stock inventory Warehouse stock management